Butterfly valve designs use a hard seat and an O-ring or piston ring around the disk to seal. Butterfly valve may include an angularly offset and disca pressure-tight resilient seat . Butterfly valvesrange in size from small to enormous, and are well suited for large flows of gases, liquids, or slurries, offer a number of advantages when used for the proper application. They may be used in a wide variety of chemical services, they are available with small dimensions allowing for use in areas where space is limited, and they allow a high coefficient of flow. Conversely, the design of butterfly valve creates the disadvantage of not being easy to clean, and therefore should be avoided in situations that call for sterile, medical or food processing applications. Additionally, some styles may have difficulty dispensing slurries.

http://www.cgvalve.com/butterfly-valve.html

Wednesday, May 23, 2007

Sunday, May 20, 2007

Check valve

Check valve

Check valves are generally used in drip irrigation emitters and irrigation sprinklers.Check valves are available in three bonnet designs. The first design is the bolted bonnet, with male-female joint, spiral wound gasket. The second design is the welded bonnet, with a threaded and seal welded joint. On request a full penetration strength welded joint is available. The other design is the pressure seal bonnet, with a threaded and pressure seal bonnet joint.There are three different design configurations of the check valves. They are piston check, swing check, and ball check designs.

Friday, May 18, 2007

Globe Valve

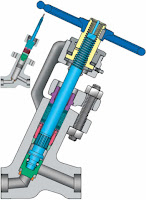

High Performance Forged One-Piece Globe Valve

- Easy disassembly and quickNo WeldsTo Remove

Designed for tough service

High Pressure-temperature Service with Low Fugitive Emmissions

Non-rotating stemand non-rising handwheel

The only valve with 22 design featuresfor high pressure steam and other tough services

In-Service valve

Wednesday, May 16, 2007

PLUG VALVE

ANSON manufacture Two types of Plug valves, the COMPACT and the PREMIER.

ANSON manufacture Two types of Plug valves, the COMPACT and the PREMIER.All ANSON Plug valves are fully tested and certified and given a unique serial number before leaving the Factory.

ANSON produce the LARGEST RANGE of extra high pressure API Plug Valves. Available from 2" to 4" full bore for pressures up to and including 15,000 psi and in some instances 20,000 psi. All Plug Valves manufactured by ANSON are of the pressure balanced type and have replaceable metal liners between the body and plug.

Valves with alternative end connections can be supplied to special order and all valves can be provided with hydraulic or pneumatic actuators. Manually operated valves with high stem torque's are fitted with gear boxes as standard. Each valve is thoroughly tested before dispatch and comes complete with fully traceable certification.

http://www.anson.co.uk/plug.html

Crane Resilient Seated Butterfly Valves Introduction

Crane has been a market leader in quarter-turn valves for more than 40 years, and we have earned a reputation as a supplier of superior valves at competitive prices. Our goal is to exceed industry requirements and customer expectations.

We are committed to offering products that meet a wide range of applications and requirements. We continually improve our product line by introducing new products and enhancing existing designs, providing our customers with the best products on the market.

Our complete line of resilient seated butterfly valves provides you with the reliability you need, backed by the guarantee that comes with using valves designed and produced in company-owned manufacturing facilities

http://www.h6688.com/valve/crane/02/0020.htm

We are committed to offering products that meet a wide range of applications and requirements. We continually improve our product line by introducing new products and enhancing existing designs, providing our customers with the best products on the market.

Our complete line of resilient seated butterfly valves provides you with the reliability you need, backed by the guarantee that comes with using valves designed and produced in company-owned manufacturing facilities

http://www.h6688.com/valve/crane/02/0020.htm

Tuesday, May 15, 2007

ball valve

ball valve

After more than ten years’ rapid development, it has formed the production scale of 20,000,000 sets of gas firing pulse lighters annually. Its capacity of production and sale leads the largest in this line in China. Bai Wei is the largest producer of gas firing pulse lighting controller with the earliest development. Bai Wei is the earliest approved by ISO9002-94 and ISO9001-2000 in this line in China.

After more than ten years’ rapid development, it has formed the production scale of 20,000,000 sets of gas firing pulse lighters annually. Its capacity of production and sale leads the largest in this line in China. Bai Wei is the largest producer of gas firing pulse lighting controller with the earliest development. Bai Wei is the earliest approved by ISO9002-94 and ISO9001-2000 in this line in China.The company has good production environment, advanced production equipment and production craftwork. Cooperating with more than four hundred companies for a long time, its sale network can be found everywhere both at home and abroad. With the management idea of “ people to be the essence with profession and concentration, redounding upon the society and customers”, the company is active in relying on the progress and innovation of technology. It follows the latest technology closely and continuously research and produce new products, which leads the market.

The company has a good environment and lies in a section with convenient traffic. Welcome to our company!

Wednesday, May 9, 2007

valva world Asia conference&exhibition

Valve World

Asia Conference & Exhibition 2007

The leading global educational and networking event for flow control professionals!

The Valve World Asia Conference & Exhibition 2007 will be held in The Shanghai International Convention & Exhibition Centre, Shanghai, China, on October 17th & 18th 2007. Following on to the huge success of past Valve World Conferences and Exhibitions, the Valve World Asia Conference & Exhibition 2007 promises to be a valuable meeting point for valve professionals from all over the world with a special emphasis on recent developments in China. Piping and valve professionals from West & East can update their knowledge of valve applications in a variety of industries with a clear focus on the chemical, petrochemical, power generation, oil & gas and process industries.

Saturday, April 28, 2007

valve world-solenoid valve

valve world-solenoid valve

1) Prevent the valve from being strongly striken in the process of installation and shipment, otherwise it may influence its normal performance.

2) Before installation, the user must check the valve flatly on the test clamps with some prepressing. It is not allowed to be freely-flip. This assures that magnetic material won’t be damaged by colliding, otherwise it will influence the magnetic force.

3) Clean the impurity such as aluminum or oil left on the inner wall of the stove and the surface of the valve.

4) Keep the good connection of the solenoid valve and thermocouple. Prevent the safety protection device from operating abnormally because of too big contact resistance.

5) The warehouse of solenoid valves must be dry and ventilated and strictly prohibit extrusion.

Subscribe to:

Posts (Atom)